How to Choose the Best Ball Screw for Sale?

Selecting the right ball screw for sale is crucial for optimizing machinery performance. Industry reports indicate that a well-chosen ball screw can enhance operational efficiency by up to 30%. For manufacturers, precision and durability are paramount. Renowned expert Sarah Johnson once said, “The best ball screw integrates seamlessly into your system, improving both speed and accuracy.”

When searching for a ball screw for sale, it's essential to consider load capacity and configuration. Different applications require different specifications. If the choice is wrong, it can lead to costly downtime and repairs. Additionally, compatibility with existing systems is often overlooked. A miscalculation here can throw a wrench in production schedules.

It’s also vital to evaluate the supplier's reputation. Quality varies widely across the market. Some vendors offer excellent products, while others do not meet industry standards. Conduct thorough research to avoid investment in subpar components. In conclusion, examining every aspect of ball screw selection will lead to better performance and less frustration in your operations.

Understanding the Basics of Ball Screws and Their Applications

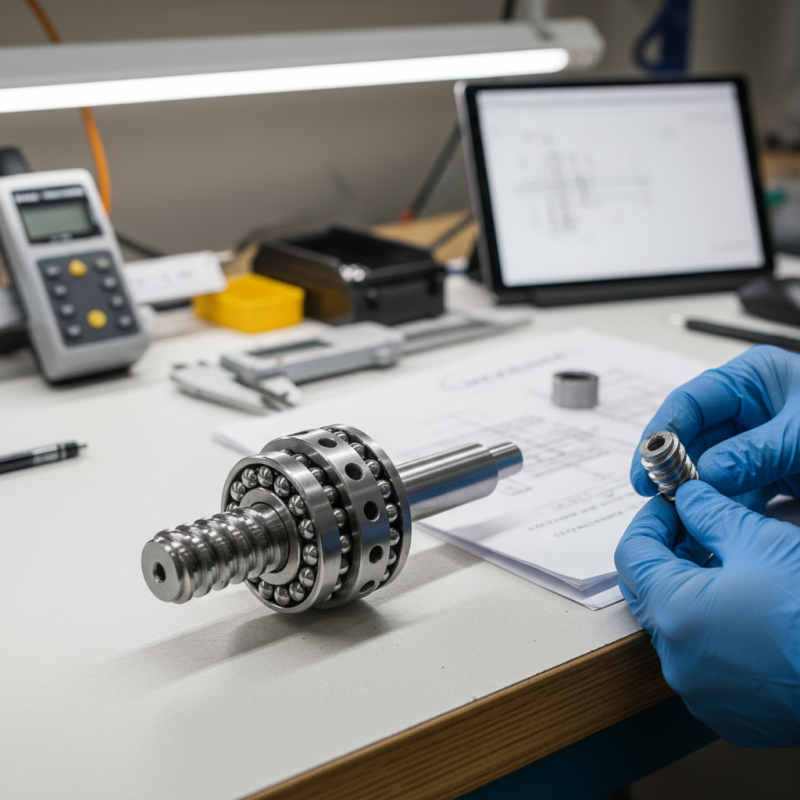

Ball screws are essential components in many mechanical systems. They convert rotary motion into linear motion efficiently. Their basic structure includes a screw, a nut, and ball bearings. These elements work together to reduce friction and wear. This design allows for smoother operation and higher precision.

Applications of ball screws are widespread. They are often found in CNC machines, robotics, and automotive systems. In manufacturing, they enhance performance by enabling faster and more accurate movement. However, not every application requires a high-end ball screw. Some operations might work fine with less expensive options.

Selecting the right ball screw can be challenging. Accuracy is critical, but so is cost. It's important to consider load requirements and potential wear. If the application demands frequent movements, a more durable model is a wise choice. However, for occasional use, a simpler design may suffice. Balancing quality and functionality is key, and sometimes, compromises might lead to better solutions in practice.

Ball Screw Load Capacity Comparison

This chart illustrates the load capacity of different ball screw models. As you can see, the load capacity increases with the model size, providing options for various applications and requirements in machinery.

Identifying Key Specifications for Selecting Ball Screws

Choosing the right ball screw can greatly impact your project. It’s essential to identify key specifications before making a decision. Load capacity is one of the primary factors. How much weight do you need to move? Understanding the load will guide your selection process.

Another crucial specification is the lead of the screw. This affects the speed and resolution of the movement. A higher lead means faster motion, but less precision. Consider your application’s requirements carefully. Do you need speed or precision? This choice is pivotal.

Tips: Always review the materials used in the ball screw. Quality can vary significantly. A lower-cost option may lead to failure. Don't rush into a purchase. Ask questions and gather information. Reflect on your specific needs before deciding. Your project may depend on this choice.

Evaluating Quality and Performance Standards in Ball Screws

When evaluating ball screws, quality and performance matter greatly. Various factors affect their overall functionality and longevity. Look for materials that are durable and resistant to wear. The design should minimize friction and promote smooth movement. Note that not every screw will meet all your needs perfectly. Sometimes, compromises are necessary based on your specific application.

Tips: Check for precise manufacturing tolerances. This ensures that the ball screw will operate efficiently. A tight tolerance can lead to improved precision in motion control systems. Additionally, review load ratings; they should align with your operational requirements. Remember that a higher load capacity often means a bulkier design.

Performance standards are crucial for reliable operation. Investigate how the ball screw performs under stress over time. Look for information about fatigue resistance and thermal behavior. Don't rush through this evaluation; patience is key. Mistakes can be costly. If the ball screw is not fit for your application, it can lead to frequent breakdowns. Reflect on what aspects are most important to you.

How to Choose the Best Ball Screw for Sale? - Evaluating Quality and Performance Standards in Ball Screws

| Ball Screw Type | Diameter (mm) | Lead (mm) | Load Capacity (N) | Accuracy Class | Material |

|---|---|---|---|---|---|

| C7 Precision Ball Screw | 25 | 5 | 5000 | C7 | Alloy Steel |

| C5 Precision Ball Screw | 32 | 10 | 8000 | C5 | Stainless Steel |

| C3 Precision Ball Screw | 16 | 4 | 2500 | C3 | Carbon Steel |

| Miniature Ball Screw | 10 | 2 | 1000 | C7 | Alloy Steel |

Comparing Different Types of Ball Screws Available in the Market

When selecting a ball screw, understanding the various types available is essential. The market offers different designs, including rolled and ground ball screws. Rolled ball screws are often more economical and suitable for higher production rates. They can handle moderate loads efficiently, making them a favorite for general applications. Reports indicate that approximately 40% of users prefer rolled screws for their cost-effectiveness in low to medium load projects.

On the other hand, ground ball screws are designed for precision. They are ideal for applications requiring tight tolerances and high reliability. Their manufacturing process results in a superior finish and performance under heavy loads. Statistical data suggests that about 30% of industries gravitate toward ground ball screws for high-precision tasks, such as CNC machinery. Nevertheless, these screws can cost significantly more, posing a dilemma for budget-conscious companies.

Considering these options, it's crucial to assess your specific needs. Factors like load capacity and accuracy will impact your decision. It’s often overlooked, but consulting with industry experts or suppliers can provide valuable insights. Gathering data from multiple sources ensures a well-rounded understanding of what type of ball screw best fits your application. Balancing cost, performance, and precision is not an easy task, and reflection on past choices can guide future decisions.

Tips for Sourcing and Purchasing Ball Screws Effectively

When sourcing ball screws, consider their accuracy and load capacity. According to industry reports, precision can impact machinery performance. A typical ball screw achieves linear accuracy of ±0.01 mm. This tolerance can significantly affect operations in high-speed applications. Additionally, the load capacity can vary based on screw size and design. Evaluate the required specifications cautiously.

Here are some tips for effective purchasing. First, clarify your application requirements. Consider factors like axial load, speed, and environment. Not all ball screws perform well in extreme conditions. Next, assess the supplier's reputation. Look for reviews and case studies. A reliable supplier can save you issues later. Finally, consider after-sales support. Maintenance and parts availability are essential for longevity.

Be cautious with pricing. Cheaper options may compromise quality. Always ask about materials and manufacturing processes. Raw material grade affects durability. Opting for inferior materials could lead to frequent replacements. Keeping these points in mind will enhance your sourcing strategy.