How to Choose the Best Stainless Steel Wire Mesh for Your Needs?

Choosing the right stainless steel wire mesh can be challenging. Experts like John Smith, a renowned material engineer, emphasize, “Quality wire mesh can significantly impact your project.” When deciding, consider your specific needs. Different applications require various specifications of stainless steel wire mesh.

For example, filtration systems need finer mesh, while safety barriers may prioritize strength. Understanding the purpose is crucial. However, many overlook this step and later regret their choices. Reflecting on your project's demands can save time and resources.

Different grades of stainless steel offer unique properties. Some resist corrosion better than others. Incorrect selection might lead to premature failure. Therefore, research and consultation with professionals are beneficial. Ultimately, the right stainless steel wire mesh enhances both functionality and longevity.

Understanding the Different Types of Stainless Steel Wire Mesh Available

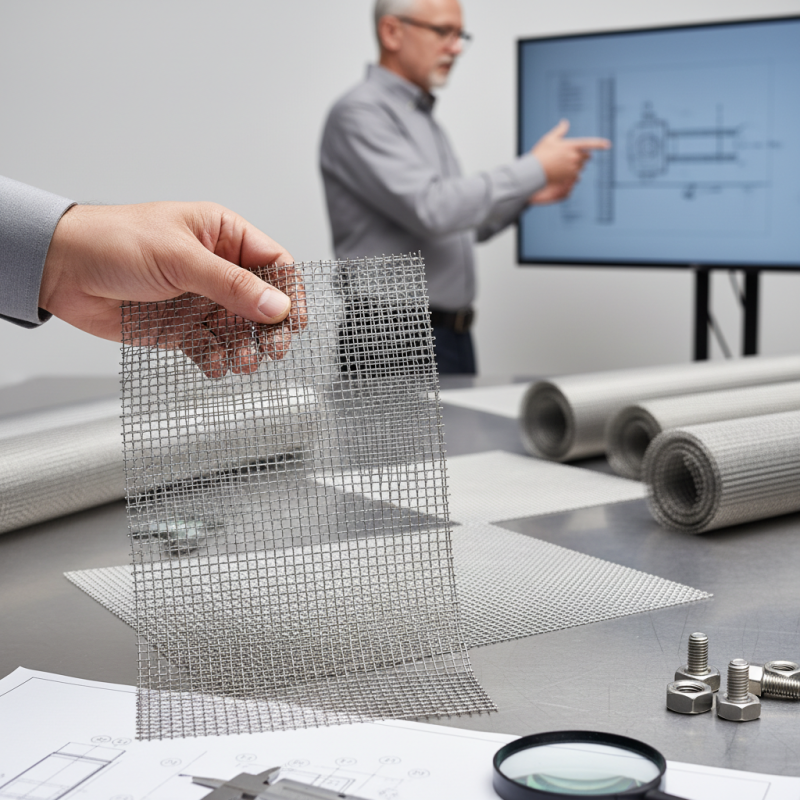

Choosing the right stainless steel wire mesh can be challenging. There are different types available, each with unique features. For example, welded wire mesh is strong and durable, making it ideal for structural applications. Its welded joints enhance stability. On the other hand, woven wire mesh offers flexibility. It can be used in filtration and decorative purposes.

Another type is perforated sheet metal. This material has holes punched through it, allowing for airflow and drainage. It’s often used in industrial settings. Each mesh type has varying wire diameters and openings. Too large an opening may not provide adequate support, while too small can hinder performance.

Understanding these details is crucial. Think about your specific needs. Consider factors like environment, weight load, and exposure to elements. Will it be exposed to moisture? Will it face heavy usage? Reflecting on these questions can simplify your decision. Choosing the right mesh makes a significant difference in functionality and durability.

Key Factors to Consider When Choosing Stainless Steel Wire Mesh

When selecting stainless steel wire mesh, a few key factors should guide your choice. First, consider the mesh size. It influences the material's filtration capabilities. For instance, smaller openings are better for fine filtering, while larger ones allow for good airflow. Think about your specific application. A balance between size and functionality is essential.

Next, the wire diameter matters. Thicker wires provide more strength and durability. However, a thicker mesh may limit flow rates. You might find yourself grappling with this trade-off. Evaluate the pressure and volume requirements of your project. Are you willing to compromise strength for greater flow?

Lastly, the type of stainless steel used impacts corrosion resistance. Different grades offer varying levels of protection. For example, 304 stainless steel is common but may not be suitable for harsh environments. You may need to rethink your options based on the environment where the mesh will be used. Each decision comes with its own set of drawbacks, requiring you to weigh your priorities carefully.

Applications and Industries Utilizing Stainless Steel Wire Mesh

Stainless steel wire mesh has diverse applications across many industries. It is commonly used in food processing, construction, and automotive sectors. According to a market study by Grand View Research, the global stainless steel wire mesh market size was valued at approximately $3 billion in 2021. This figure highlights its significance due to high durability and corrosion resistance.

In the food industry, this mesh is crucial for filtration and separation processes. For instance, it ensures safety when processing meats. The automotive sector relies on it for manufacturing filters and screens. Yet, there are challenges. Selecting the right type can be tricky. Different grades of stainless steel and mesh sizes can greatly affect performance. An incorrect choice may result in product failure.

The construction industry also benefits from stainless steel wire mesh. It enhances concrete strength and stability. However, issues can arise if not correctly aligned with project specifications. Accurate sizing and spacing are vital for maintaining structural integrity. A mismatch could lead to costly repairs later. Overall, understanding the specific applications is essential for making the right choice in wire mesh.

Comparing Wire Mesh Specifications and Grades for Optimal Selection

Choosing the right stainless steel wire mesh begins with understanding specifications and grades. Stainless steel is categorized mainly by its alloy composition. The most common grades are 304 and 316. Grade 304 is often used for its excellent corrosion resistance, but it might not withstand harsh chemicals. In contrast, grade 316 provides better chemical resistance due to its molybdenum content. According to a report by the Metal Research Institute, 316 stainless steel can resist corrosion in marine environments significantly better than 304.

Mesh specifications include wire diameter and aperture size. Wire diameter impacts the mesh strength and filtration capabilities. A thicker wire generally provides higher tensile strength. On the other hand, larger apertures are crucial for specific applications like filtration and ventilation. Studies show that a 0.028-inch wire diameter with a 1/4-inch aperture can filter out particles down to 50 microns effectively. However, overestimating the required mesh strength may lead to unnecessary costs.

Another factor to consider is the mesh count. Higher mesh counts increase filtering efficiency but can strain flow rates. An improper balance may result in clogging or increased maintenance. This trade-off often gets overlooked. Selecting the best wire mesh requires a careful assessment of these variables to meet specific needs without overspending. Consult technical data sheets and industry reports for precise specifications tailored to your application.

Maintenance and Care Tips for Stainless Steel Wire Mesh Products

Stainless steel wire mesh offers excellent durability and strength. However, proper maintenance is essential for longevity. Regular cleaning is vital. Dust, debris, and grease can accumulate over time. A simple rinse with water can remove light contaminants. For tougher stains, a mild detergent works well. Use a soft brush for scrubbing, ensuring you do not scratch the surface.

Inspect the mesh regularly for signs of wear or corrosion. Even high-quality stainless steel can rust if neglected. Address any issues early to avoid costly damage. If rust appears, treat it promptly. You can use a rust remover or sandpaper for minor spots. Remember, prevention is key. Store the wire mesh in a dry place to minimize exposure to moisture.

While stainless steel is resistant to corrosion, it is not invincible. Sometimes, despite the best care, the mesh may still show wear. This is a reminder that nothing lasts forever. Adapting your maintenance routine based on the environment is essential. In coastal areas, increased humidity can accelerate corrosion. A little reflection on these factors can save time and money.