2026 How to Choose the Right Welded Wire Mesh for Your Needs?

Choosing the right welded wire mesh can be overwhelming. Different applications require different specifications. An expert in the field, John Smith, once stated, “Selecting the correct welded wire mesh is crucial for structural integrity and functionality.”

welded wire mesh is used in various industries. It offers strength and durability for fences, reinforcement, and construction. However, not all mesh types are suitable for every project. The wire gauge, mesh size, and coating are essential factors to consider. A wrong choice may lead to structural failure or increased costs.

Consider your specific needs carefully. Reflect on the environment where the welded wire mesh will be used. Will it be exposed to moisture or corrosive materials? Each decision affects the overall performance. Ultimately, finding the right fit requires both knowledge and reflection on your unique situation.

Understanding the Basics of Welded Wire Mesh Specifications

Welded wire mesh is crucial for various applications. Understanding its specifications helps in choosing the right type. Factors like wire diameter, mesh opening size, and material type influence its strength and durability. Common materials include stainless steel, galvanized iron, and PVC-coated options. Each material serves different purposes based on environmental conditions.

When assessing mesh specifications, consider the wire diameter. Thicker wires provide more strength, while thinner wires offer flexibility. Likewise, the mesh opening size affects visibility and airflow. Smaller openings prevent pests, while larger openings allow better circulation. Think about your specific needs before making a decision.

It's important to reflect on how the wrong choice can lead to issues. A mismatch in expected strength can result in project failures. Additionally, forgetting to consider environmental exposure can lead to corrosion or degradation. Always evaluate your requirements carefully before purchasing welded wire mesh.

Identifying Your Project Requirements and Applications

When selecting welded wire mesh, understanding your project requirements is vital. Different applications call for specific mesh specifications. For example, construction projects often prefer robust mesh types, while gardening might require lighter solutions. According to the International Wire and Wire Products Association, welded wire mesh's strength grade must align with the intended load-bearing capacity.

Consider the mesh size that suits your needs. A fine mesh works well for small animals or plants, while larger openings support heavy machinery. Misjudging this can lead to failures or insufficient support. Think about corrosion resistance too. In outdoor applications, galvanized or stainless steel options are essential. A report from the American Concrete Institute highlights the importance of selecting the right material to avoid rust and ensure longevity.

Additionally, reflect on the installation environment. Will the mesh be exposed to moisture or chemicals? These factors heavily influence your decision. Some installers overlook this, leading to premature wear and costly repairs. The mesh's details matter; even the weld spots can affect durability. Small flaws might seem insignificant but can compromise overall performance. Not every choice will be perfect, and that’s okay. Each project offers lessons for improvement.

Evaluating the Different Types of Welded Wire Mesh Materials

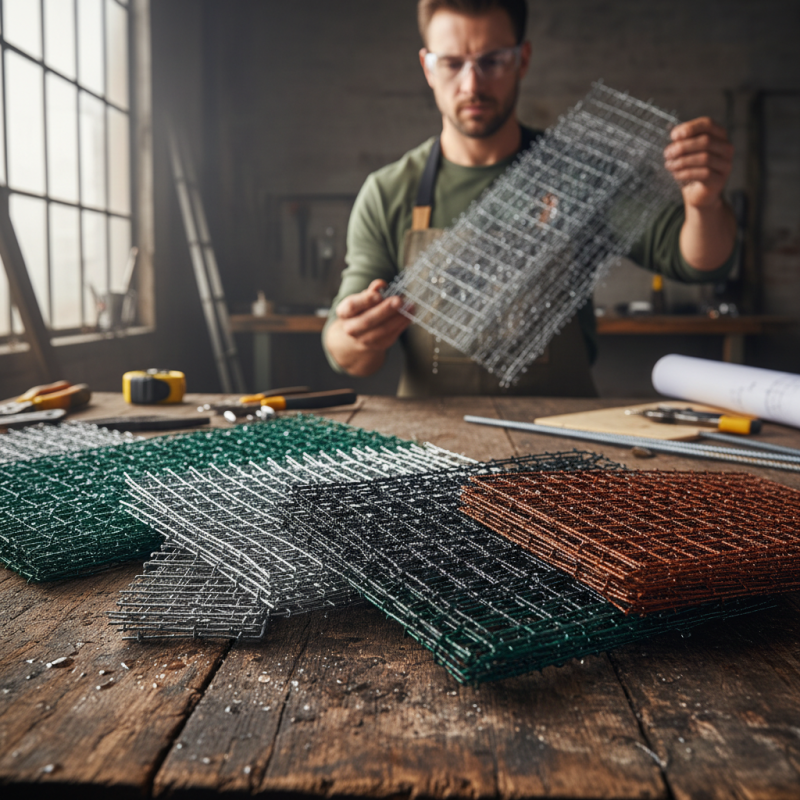

When selecting welded wire mesh, understanding the materials is crucial. Common types include galvanized steel, stainless steel, and PVC coated wire. Galvanized steel is popular for its rust resistance. It's suitable for outdoor applications. However, it may not be ideal in marine environments.

Stainless steel offers enhanced durability. It withstands corrosion in harsh conditions. Yet, this material often comes at a higher cost. PVC-coated wire mesh provides a colored, protective layer. It is visually appealing and adds extra corrosion resistance. However, the coating might wear off over time, diminishing its effectiveness.

Each type has its pros and cons. Choosing the wrong mesh can lead to increased maintenance or early replacements. For fans of DIY, remember that the perfect fit means balancing cost with quality. Reflect on your specific needs before making a choice. Think about the environment where it will be used. Do you need something long-lasting? Or is a temporary solution enough? Each scenario requires careful consideration.

Considering Wire Diameter and Wire Spacing for Strength

When selecting welded wire mesh, the wire diameter and spacing are crucial for strength. Industry reports suggest that a thicker wire (such as 12 or 14 gauge) offers better durability for heavy-duty applications. As the wire diameter increases, so does the mesh’s overall strength. This is essential in applications like fencing or supporting structures.

Mesh spacing also plays a vital role. Wider spacing (like 4 inches) allows for more significant visibility but may compromise strength. Conversely, tighter spacing (around 2 inches) can enhance support but may increase material cost. Most experts recommend evaluating the purpose before deciding the spacing.

Tips: Always assess the weight and impact your mesh will endure. If unsure, consult with industry professionals for tailored advice. Remember, overshooting required specifications can lead to unnecessary expenses. It's essential to find a balance between strength and cost-effectiveness.

Comparing Cost and Durability Factors in Welded Wire Mesh Choices

When choosing welded wire mesh, cost and durability are crucial factors. According to a recent report by the Wire Mesh Institute, welded wire mesh can range from $0.15 to $2.00 per square foot. The price varies based on material gauge, mesh dimension, and finish. Thicker wires offer greater strength but come at a higher cost. Understanding these price variations can help you make informed choices.

Durability is another key consideration. The lifespan of welded wire mesh typically spans 10 to 30 years, depending on environmental conditions and usage. For outdoor applications, galvanized mesh resists rust and corrosion better than plain steel mesh. In wet climates, investing in higher-quality materials can actually save costs in the long run due to reduced need for replacements.

It's essential to balance cost and performance. Cutting corners on cheaper options may lead to higher maintenance costs later. Evaluate your specific needs carefully. Reflect on where and how the mesh will be used. Will it bear heavy loads, or support lighter functions? A well-thought-out selection process can prevent regrets down the line.